Delfi Barcode guide

What is a barcode and what do the different numbers, combinations, letters and different formats mean?

When you need an overview of goods and stock flow, you can’t do without barcodes. Today, barcodes are a must in modern and efficient inventory management. With many different types of barcodes for different needs, the barcode jungle can be a challenge to navigate. That’s why we’ve created this barcode guide to give you an overview of the most useful barcode types and frequently asked questions. Barcodes may not get much attention from you, but have you ever wondered where barcodes come from? What is a barcode and what do the different numbers, combinations, letters and different formats mean?

The story behind the barcode

End 1940

Inspired by Morse code, the idea of using barcodes was developed by Norman Joseph Woodland and Bernard Silver in the late 1940s. Morse code was usually applied via sound or light. For example, a short sound followed by a longer sound means the letter A. In this way, words could be formed from sounds or lights, in various combinations. This technology was then transferred to print as what we know a barcode for today, namely thick and thin lines in combinations.

1952

Woodland and Silver had their patent application for the actual barcode and barcode scanner approved in 1952. The first time barcodes were used commercially was on train cars. Each car on the train had its own barcode on the side of the car. The barcode indicated information about the owner, equipment types and identification number. The barcodes were read by a tracking scanner placed at the entrance to a shipyard, for example, as the train passed by.

1974

It was in June 1974 that the first barcode ever scanned was a Universal Product Code (UPC) barcode on a pack of Wrigley's chewing gum at Marsh's store in Troy, Ohio. Today, barcodes play a particularly important role in improving the way companies capture and share information and optimize the flow of goods in the supply chain.

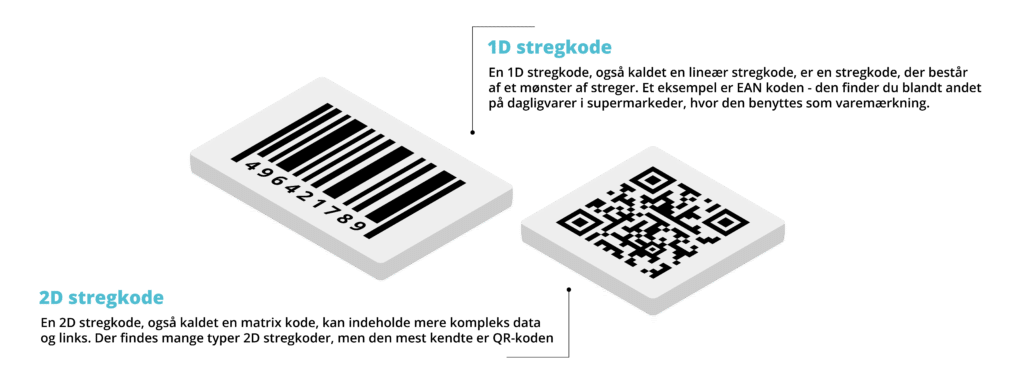

What’s the difference between 1D and 2D barcodes

There are generally two different classes of barcodes – 1D and 2D barcodes. The 1D code is the barcode you know from the milk carton or your health insurance card. The 2D barcode, also known as a QR code, you may have scanned with your smartphone when you downloaded an app from a magazine or similar. It’s not just the layout of the barcode that makes the difference between the two types of barcodes, but more importantly the functionality of the barcode. The big difference between the two classes is the amount of data that the barcode can hold. 2D barcodes can hold much more data than 1D barcodes.

1D Barcodes

1D barcodes, also known as linear barcodes, are the most common type of barcode. It’s the code you encounter most often and the one most people typically associate with a barcode. The 1D code is the most commonly used barcode and is mainly found on consumer goods in retail. The traditional 1D barcode consists of a series of bars and spaces of different widths to encode information.

This type of barcode can contain a limited number of characters, otherwise the barcode will be too long. The more characters the 1D barcode contains, the longer (wider) the code will be.

On consumer goods in retail, barcodes are used as a unique product identifier. Here, the first two digits of the barcode typically indicate the country of registration, but not necessarily the country of origin. The next five digits are a marketing number for the manufacturer, importer, wholesaler or retailer. The next five digits are the marketer’s internal item number and the last digit is a check digit.

2D Barcodes

2D barcodes use patterns of squares, dots and other shapes to encode data. Due to the structure of the 2D barcode, it can hold more data than the simpler 1D barcode. Where the 1D barcode usually contains 8-15 characters, the 2D barcode can contain up to 2000 characters and can be displayed in very small sizes. The data is encoded on both horizontal and vertical patterns and can communicate much more complicated tasks. Therefore, 2D barcodes also require improved scanning equipment in the form of 2D barcode scanners and 2D

Unlike the 1D barcode, the 2D barcode can also contain images, URLs, speech and other types of binary data. This means that much more information can be read from this barcode. A 1D barcode scanner can only read 1D barcodes, not 2D barcodes.

2D barcode scanners are often used to read 2D barcodes, although some 2D barcodes, like the well-known QR code, can also be read with a smartphone. Most 2D barcode scanners can also read 1D barcodes, which provides greater flexibility as you don’t need a barcode scanner for different types of barcodes. So unless you have a basic need to only read 1D barcodes, it can be beneficial to upgrade and future-proof your barcode scanner to a 2D scanner.

The advantage of 2D barcodes

The structure of the 2D barcode also includes error correction measures to ensure that it can still be read even if it is partially destroyed or damaged – for example during transportation or simply worn over time. 2D barcodes are therefore less vulnerable to scratches, bad printing and the like. The barcode provides sufficient redundant data and is encoded to reconstruct the original information, even with significant parts missing.

Which barcode should I choose?

Under the two different types of barcodes, there are also a number of other subclasses of barcodes. You should therefore choose the type(s) of barcodes that meet your needs. The most well-known types of 1D barcodes are EAN (European Article Numbers) and UPC (Universal Product Code). These are the ones you primarily know from the retail industry. Where you often see the GS1-128 barcode in logistics contexts. There are also many other types of barcodes that are not used as often. If you need help finding the right

EAN-13 is composed as follows: The first two digits of a barcode indicate the country of registration, but not necessarily the country of origin. The next five digits are a marketer number for the manufacturer, importer, wholesaler or retailer. The next five digits are the marketer’s internal item number and the last digit is a check digit. This barcode is the most commonly used in Danish retail.

The UPC-A is used in the same way as the EAN barcode. Although there are several different types of barcodes, the UPC symbol appears on almost every retail product in the United States, making it the most versatile and recognizable type of product code in this part of the world, and is also commonly used in Canada, Europe, Australia and New Zealand. It consists of 12 numeric digits assigned to each individual item. EAN and UPC are very similar, but each has its own main geographical area of use.

The GS1-128 barcode was developed to create a global standard for the exchange of data between different companies. The barcode is typically used for labeling packages and pallets in a logistics context, i.e. warehouse or transport handling.

While the EAN-13 barcode only contains a GTIN (Global Trade Item Number), the GS1-128 barcode can contain a wide range of information, including production or shelf life dates, weight and batch numbers, typically information that varies each time the product is traded. The information is encoded in the GS1-128 barcode using Application Identifiers (AI) and their associated data fields. It can contain 48 alphanumeric characters in one barcode.

What is the difference between UPC-A and EAN-13 barcodes?

Both types of barcodes are used in businesses worldwide, the main difference is that UPC-A is the most preferred in the US while EAN-13 is the most common in all other countries. The encryption of the two is very similar. We only recommend using UPC-A barcodes if you are dealing with products that will be sold mostly in the US, and vice versa, using EAN-13 barcodes on products for all other countries would be the best solution.

Print labels and barcodes – in your own layout

It is possible to design and print your own barcodes and labels with a label program. There is user-friendly software that makes this task more manageable. Many companies today use

Seagull Scientific is a recognized manufacturer of label software that we have worked closely with for many years. If you want your barcode/label to look a certain way, or have your logo or something else on the label, you should use BarTender. If you want a free trial version, you can always contact us.

BarTender offers a range of dynamic features and benefits to help you increase productivity.

With BarTender, you can get help with things like

- Accelerate the speed of goods moving through the supply chain

- Get the right medicine to the right patient – on time

- Make sure employees know how to handle hazardous chemical substances

- Warn a parent about a potentially harmful allergenic substance

- Enable health authorities to trace a foodborne illness back to where it originated

- Improve retail shrinkage control and loss prevention

- And much more…

Future alternatives to barcodes

RFID – is an abbreviation for “Radio Frequency IDentification” and uses a technology where digital data is encoded into RFID tags or labels and then captured by an RFID reader via radio waves. The way RFID is used is similar to barcoding in that data from a label or tag is captured by a device, but here all available RFID tags and associated information are stored in a database at once – quickly and easily. However, one notable difference is that RFID tags can be read without being in direct line of sight. An example of an application could be a clothing store that has RFID labels on all their products. During the annual inventory count, RFID technology makes it possible to collect data from all items at the same time using an RFID reader that can read RFID tags from up to 30 meters away. Another example of use:

Digimarc – is an advanced invisible barcode that provides recognition via sound and image. When using Digimarc as a barcode type, product wrapping, packaging and the like are transformed into an online interactive barcode. Subsequently, when a product is scanned with, for example, a mobile device, the user/clerk can obtain information about the product, which is linked to an online database. The technology is known in wine apps, for example. When a picture of a wine is taken, you can get information about which country it is from, price, product information, etc.

Direct part marking (DPM) – is a method for permanent marking with 2D codes with product information, serial numbers, date codes and barcodes etc. 2D-QR codes can be printed with laser engraving. This method is used in industries where permanent marking is a must. In the aerospace industry, an aircraft part can be in service for more than 30 years, where DPM can be an advantage to facilitate reliable identification of the parts. DPM can help with data logging for safety, warranty issues and satisfying regulatory requirements.